Meet Sustainability Goals

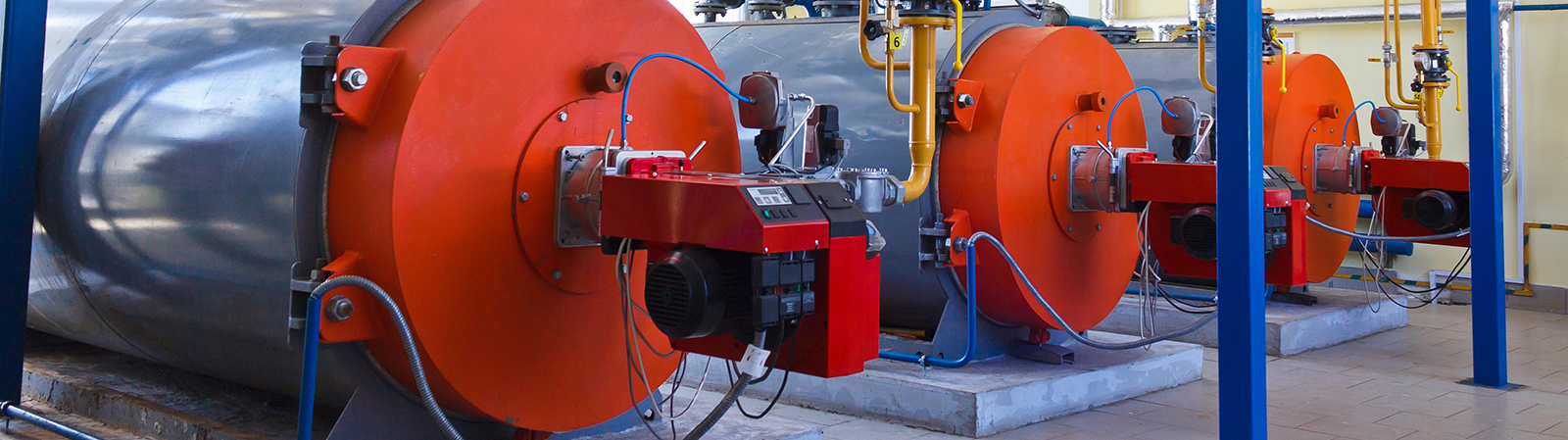

Advanced burner control solutions from NECI allow for increased efficiency in fuel usage and reduced carbon emissions. Modern burner controls enable systems to respond to downstream process demands resulting in more environmentally sustainable operations and reduced costs, while exceeding strict modern efficiency guidelines.

Modern burner controls allow for greater efficiency in fuel usage and tune the boiler system to respond to downstream process demands. This results in a more environmentally sustainable system and lower costs, as well as a means to achieve efficiency compliance levels.

Modern burner controls allow for greater efficiency in fuel usage and tune the boiler system to respond to downstream process demands. This results in a more environmentally sustainable system and lower costs, as well as a means to achieve efficiency compliance levels.  Modern burner management platforms allow for more complex control of utilities in coordination with each other. Operators are informed and empowered to adjust the output of the boiler systems in concert with the needs of the process operation.

Modern burner management platforms allow for more complex control of utilities in coordination with each other. Operators are informed and empowered to adjust the output of the boiler systems in concert with the needs of the process operation. Increased visibility of control interlocks reduces the need for troubleshooting and associated downtime. Operators are supplied with the data to proactively detect problems prior to a trip event.

Increased visibility of control interlocks reduces the need for troubleshooting and associated downtime. Operators are supplied with the data to proactively detect problems prior to a trip event. Replacing old, unsupported components with new OT systems increases safety, reduces risk, improves reliability, and ensures compliance with modern codes including NFPA 54/85/86/87 and ASME CSD-1.

Replacing old, unsupported components with new OT systems increases safety, reduces risk, improves reliability, and ensures compliance with modern codes including NFPA 54/85/86/87 and ASME CSD-1.